[page 50]

Appendix 1

Suggested initial equipment for a metal workshop for twenty boys

1. Power-driven equipment

2, motorised lathes, 3½-inch, back-geared, screwcutting, if possible with boring table as standard fitting.

2, 3-inch self-centring chucks.

1, 4-inch 4-jaw independent chuck.

1, drill chuck on morse taper, ½-inch capacity.

1, faceplate.

1, angle-plate, 3½-inch by 2½-inch by 2½-inch.

1, steady.

6, lathe carriers, to teacher's specification.

Lathe tool-holders and tools to teacher's specification.

1, motorised drilling machine and chuck, ½-inch capacity, with drill vice.

1, motorised double-ended grinder, 8-inch wheels, with extension spindles for polishing-mops.

1, power hacksaw, 3-inch capacity.

1, small power-blast forge, 3-foot hearth, with hood, water-cooled tue-iron.

2. Hand machines

1, hand drilling machine and chuck, 2-speed, ½-inch capacity, with drill vice.

1, hand-lever shearing machine, 5-inch blades.

3. Fixed equipment

1, brazing-hearth.

2, gas blowpipes, ½-inch, with light rubber tubing.

2, double-acting foot-bellows.

2, tinman's gas soldering-stoves, with flexible metallic tubing.

21, parallel bench vices, cast-iron with hardened steel jaws, 20, 4-inch, 1, 5-inch.

1, smith's leg-vice, 4-inch.

1, bench flatting-block, 12-inch by 12-inch by 2-inch, cast-iron, one face finely machined.

1, bench cutting-block, 12-inch by 12-inch by 2-inch, cast-iron, one face roughly machined.

4. Forge equipment

2, anvils, 1-cwt., with cast-iron stands.

12, tongs, to teacher's specification.

2, hot setts, cold setts, flatters, hardies.

2, top and bottom fullers, 1, ¼-inch, 1, ½-inch.

[page 51]

1, top and bottom swage, ½-inch.

2, sledge hammers, 1, 4-lb., 1, 5-lb.

2, hand hammers, 2-lb.

1, water trough.

1, small fuel bin.

1, shovel, poker, rake.

1, gas poker.

5. Measuring and setting-out tools

20, stainless steel rules, 12-inch, graduated one edge in eighths, the other in sixteenths and thirty-seconds.

1, smith's brass rule, 2-foot, 2-fold,

22, engineer's squares, 20, 4-inch, 2, 6-inch.

1, tinman's square, 24-inch by 12-inch.

10, centre punches.

10, scribers.

5, spring dividers, 6-inch.

10, calipers, 6 outside, 2 inside, 2 jenny.

1, centre gauge.

1, adjustable bevel.

1, surface-plate, 12-inch by 1o-inch.

1, scribing block.

1, vee-block and clamp.

1, micrometer caliper, 0 to 1-inch.

1, wire gauge, S.W.G.

6. Bench tools and general equipment

22, engineer's ball-pane hammers, 20, 12-oz., 2, 1½ lb.

6, double-ended planishing hammers, 4-oz., flat and convex faces.

12, shaping hammers, to teacher's specification.

2, hand-vices, 2-inch jaws.

1, pin-vice.

8, pliers, 4 flat-nosed, 2 round-nosed, 2 sidecutting.

12 dozen, handled files, to teacher's specification.

10, hacksaws, 8-inch soft-backed blades, 24 and 32 teeth per inch.

4, junior hacksaws.

2, piercing saws.

2, coping saws.

2, brass back-saws.

10, cold chisels, to teacher's specification.

4, hand drills, ¼-inch capacity.

Twist drills, H.S.S., 1/16-inch to ½-inch by sixty-fourths.

Twist drills, H.S.S., jobber's 0 to 40.

Twist drills, C.S., 6 each, 1/16-inch to ¼-inch, by thirty-seconds.

4, Slocomb drills.

2, countersink drills, 1, 3/16-inch shank, 1, 3/8-inch shank.

Whitworth taps, 5/16, 3/8, ½-inch, taper and plug in each size.

Whitworth dies, as taps.

[page 52]

B.S.F. taps, ¼, 5/16, 3/8, ½-inch, taper and plug in each size.

B.S.F. dies, as taps.

B.A. taps, 0, 2, 4, 5, 6, taper and plug in each size.

B.A. dies, as taps.

Tap wrenches and die stocks suitable.

Spanners, ¼-inch to 1-inch by sixteenths.

1, adjustable spanner, 10-inch.

6, screwdrivers, 3, 4-inch, 3, 6-inch.

5, small chipping-blocks.

Letter and number punches for steel, 3/16-inch.

4, oilcans.

4, file brushes.

4, bench brushes.

First-aid kit.

7. Sheet metal equipment

6, soldering-bits, 8-oz., 3 straight, 3 hatchet.

6, tinman's snips, 8-inch, straight, open-ended handles.

2, tinman's snips, 8-inch, curved, open-ended handles.

2, tinman's snips, 10-inch, straight, open-ended handles.

1, universal shear, 10-inch,

2, folding-bars, 10-inch.

2, rivet setts, 1, 1/8-inch, 1, 3/16-inch.

6, mallets, rawhide.

4, mallets, boxwood doming.

2, leather sandpads, 10-inch.

2, funnel stakes.

2, bick irons.

2, extinguisher stakes.

1, canister stake.

1, tinman's horse with 6 heads to teacher's specification.

2, hatchet stakes.

1, half-moon stake.

1, creasing iron.

1, tinman's anvil.

2, earthenware pickle troughs.

2, brass pickle tongs.

2, calico mops, 9-inch.

[page 53]

Appendix 2

Suggested initial equipment for subsidiary metalwork for six boys

1. Hand machines

1, hand drilling machine and chuck, 2-speed, ½-inch capacity, with drill vice

1, hand-lever shearing machine, 5-inch blades.

2. Fixed equipment

1, circular combination forge and brazing-hearth, 20-inch pan.

1, gas blowpipe, ½-inch, with light rubber tubing.

1, tinman's gas soldering-stove, with flexible metallic tubing.

6, parallel bench vices, cast-iron with hardened steel jaws, 4-inch.

1, bench flatting-block, 9-inch by 9-inch by 1½-inch, cast-iron, one face finely machined.

3. Forge equipment

1, anvil, ½-cwt.

4, tongs, to teacher's specification.

1, hot sett, cold sett, flatter, hardie.

1, sledge hammer, 4-lb.

1, water trough.

1, small fuel bin.

4. Measuring and setting-out tools

6, stainless steel rules, 12-inch, graduated one edge in eighths, the other in sixteenths and thirty-seconds.

6, engineer's squares, 4-inch.

1, tinman's square, 24-inch by 12-inch.

3, centre punches.

3, scribers.

2, spring dividers, 6-inch.

3, calipers, 1 outside, 1 inside, 1 jenny.

1, surface plate, 9-inch by 6-inch.

1, scribing-block.

1, wire gauge, S.W.G.

5. Bench tools and general equipment

6, engineer's ball-pane, hammers, 12-oz.

2, double-ended planishing hammers, 4-oz., flat and convex faces.

4, shaping hammers, to teacher's specification.

1, hand-vice, 2-inch jaws.

3, pliers, 1 flat-nosed, 1 round-nosed, 1 sidecutting.

3 dozen, handled files, to teacher's specification.

[page 54]

2, hacksaws, 8-inch soft-backed blades, 24 teeth per inch.

1, junior hacksaw.

1, piercing saw.

1, brass-back saw.

2, hand drills, ¼-inch capacity.

Twist drills, H.S.S., 1/16-inch to ½-inch by thirty-seconds.

Twist drills, C.S., 3 each, 1/16-inch to ¼-inch by sixteenths.

1, countersink drill, 3/16-inch shank.

Whitworth taps, 5/16, 3/3, ½-inch, taper and plug in each size.

Whitworth dies, as taps.

B.A. taps, 0, 2, 4, 5, 6, taper and plug in each size.

B.A. dies, as taps.

Tap wrenches and die stocks suitable.

1, adjustable spanner, 10-inch.

2, screwdrivers, 1, 4-inch, 1, 6-inch.

2, small chipping-blocks.

Letter and number punches for steel, 3/16-inch.

1, oilcan.

2, file brushes.

6. sheet metal equipment

2, soldering-bits, 8-oz., 1 straight, 1 hatchet.

3, tinman's snips, 8-inch, straight, open-ended handles.

1, tinman's snips, 8-inch, curved, open-ended handles.

1, folding-bar, 10-inch.

2, rivet setts, 1, 1/8-inch, 1, 3/16-inch.

2, mallets, rawhide.

2, mallets, boxwood doming.

1, leather sandpad, 10-inch.

1, funnel stake.

1, bick iron.

1, extinguisher stake.

1, hatchet stake.

1, creasing-iron.

1, earthenware pickle trough.

1, brass pickle tongs.

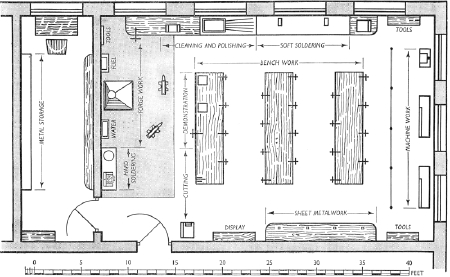

Appendix 3

Layout of workshop equipment

(see facing page)

[page 55]

[click on the image for a larger version]

The grouping of processes and the minimum safe width of passageways between equipment in a metal workshop 850 square feet in area

[click on the image for a larger version]

The grouping of processes and the minimum safe width of passageways between equipment in a metal workshop 850 square feet in area